Advanced Corrosion Mapping

The WheelProbe 2 features a captive array in an adaptive rubber wheel making it a perfect corrosion mapping solution for large surface.

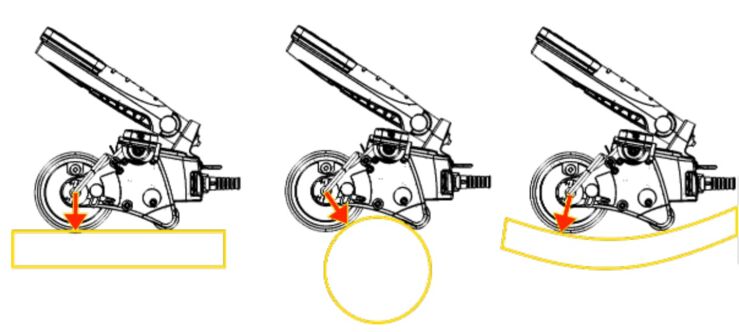

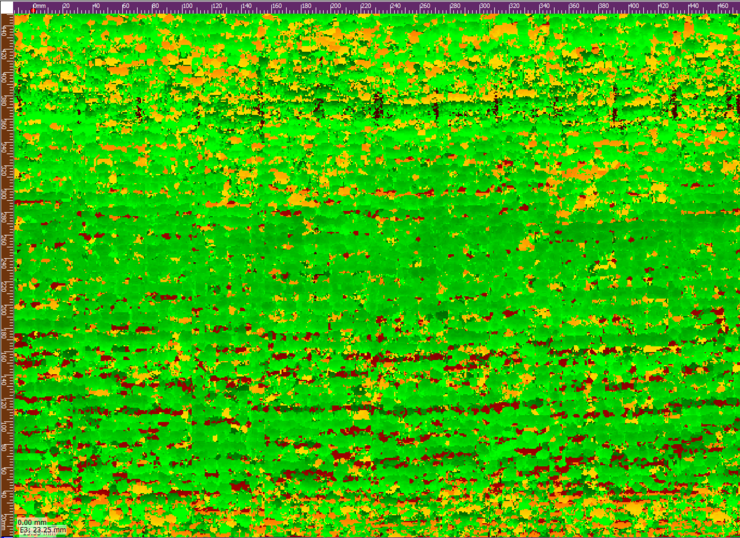

This corrosion mapping solution is perfect for large surfaces. The WheelProbe 2 features a captive array in an adaptive rubber wheel. Once filled with water, it becomes a portable immersive system that also significantly improves the accuracy of the overall inspection data. Moreover, because the encoder is fixed directly onto the WheelProbe 2, it cannot slip on the surface inspection as the wheel moves forward. This system, combined with the recording capabilities of the Veo3, accelerates inspection productivity. Results can then be reviewed with the powerful UTstudio+ or with UTmap for more advanced automatic defect detection.

|

|

|

|

|

|

|

|

|

|

|

|

Recommended Package

| Category | Part Number | Description |

| Product | Veo3 16:64PR BNC or Veo3 16:64PR LEMO |

Veo3 16:64 PR / 2UT:PR BNC or Lemo |

| Product option | SW-Veo3 CSV | Export data to CSV file |

| Probe | WP2-5MHZ-64 |

|

| Probe option #1 | WP2-PACK1 |

|

| Probe option #2 | WP2-ADV-KIT2 |

|

| Software | UTMAP | Software suitable for C-Scan analyses |

For further information, please contact the Sonatest Sales Team: sales@sonatest.com