Austenitic Stainless Steel Solution DAAH – Dual Linear Array Probe

300 series stainless steels are the most common sub-group of austenitic steels and are used in a large variety of processes and industries, typically for corrosion resistance of high temperature service. Comprehensive inspection techniques are vital to ensure safe operation.

300 series stainless steels are the most common sub-group of austenitic steels and are used in a large variety of processes and industries, typically for corrosion resistance of high temperature service. Comprehensive inspection techniques are vital to ensure safe operation.

The amount and ratio of chromium and silicone in stainless steel can cause signal attenuation and noise, making inspection a challenging task. The conventional ultrasonic approach has limitations, while the combination of linear array, focusing and beam-forming provide improved and broader inspection capabilities.

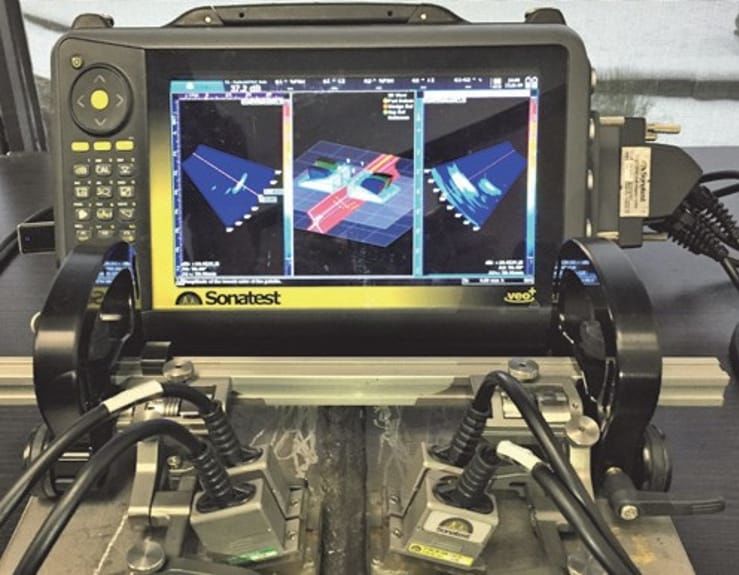

The new DAAH (detachable active array head) coupled with DLA (dual linear array) solution from Sonatest are specifically designed and developed for such application challenges.

|

|

|

|

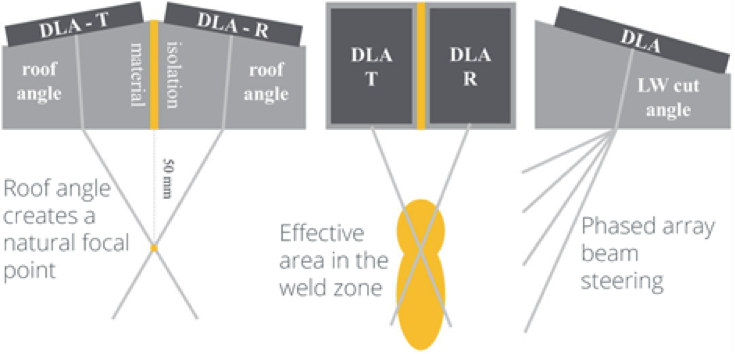

Advantages of TRL technique with DLA configuration

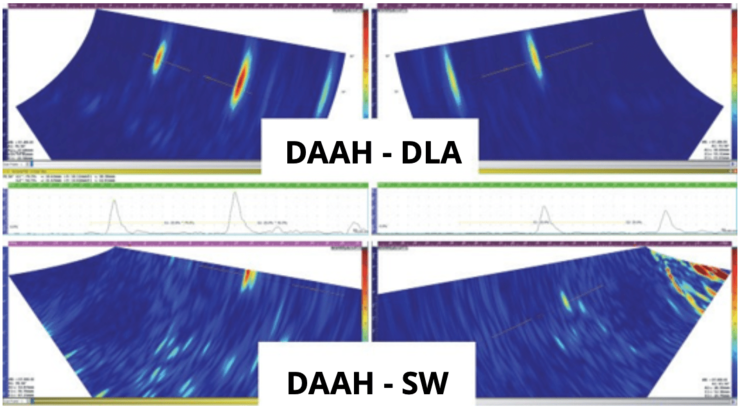

Sonatest DAAH-DLA and Veo+ solution cleverly combines the transmit-receive-longitudinal (TRL) and phased array techniques, isolating the transmitter from the receiver to create a pitch and catch configuration for a better SNR. Moreover, experience has shown that compression waves work better than shear waves for stainless steel inspection.

|

|

|

|

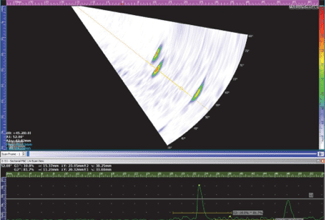

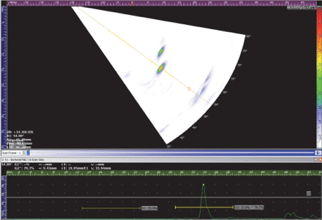

Inspection of austenitic stainless-steel welds is challenging due to the wide range of alloys and weld configuration. Moreover, Stainless steel microstructure generates beam scattering, yielding a low signal to noise ratio (SNR). It has also anisotropic property and velocity change in between the weld and the base metal which could generate mode conversion and beam distortion. If the wavelength formula would suggest to lower the probe frequency for such attenuative material, experience conduct internally has shown that sometimes, for DLA longitudinal wave, some stainless-steel sample had a much better signal quality with higher frequency. Moreover, high frequency increase sizing capability of such solution.

Some screen capture of an 316 stainless steel sample inspected with three different DLA set ups at 2.25, 5 and 7.5 MHz probes. Only trial on the material will determine the best frequency and hence the ability to quickly switch with a DAAH probe is a great help to speed up the process.

|

|

|

|

|

|

The following illustrates the arrangement of the DLA probe inspection.

|

Front |

|

Top |

|

Side |

|

|

||||

- The large aperture probes, low profile wedge and the pitch and catch configuration enhance the signal penetration and signal-to-noise ratio.

- The linear array coverage and resolution advantage combined with the wide range of probe frequencies available significantly improves the sizing capability.

For further information or support, please contact the Sonatest Applications Team: applications@sonatest.com.