Pipecheck Analyse

Overview

Fully compatible with Sonatest's ultrasonic testing instruments, Pipecheck sets a new standard of reliability and efficiency for pipeline integrity assessment teams.

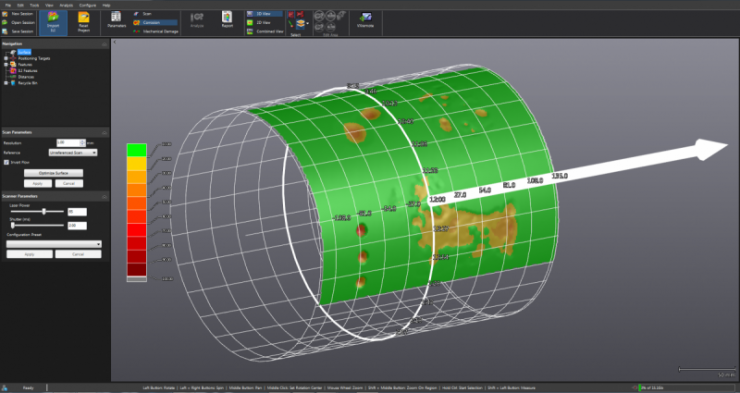

With the help of Sonatest encoded corrosion mapping solutions like the WP2/veo+ package or a manual technique with the MASTERSCAN series, NDT inspectors can directly benefit from the Pipecheck software's rigorous analysis power to calculate a pipe's bust pressure based on the wall deterioration.

This comprehensive solution provides the best solution on the market whether the need is for internal corrosion assessments, ILI correlations or true wall thickness assessments (when combined to the power of portable 3D scanners).

Features

- Workflow oriented interface (Pipecheck 4).

- UT data set importation and 3D mapping tools.

- Interaction rules are automatically applied to features.

- Burst pressure calculations (ASME B31G, B31G Modified and Effective Area methods).

- Worst-case-profile and customisable grid resolution for all features.

- Feature dimensions (length and width) and maximum depth extracted for all features.

- Snipping tool for additional reporting information.

- Assessment performed on internal and external surface of the pipeline or on the true wall thickness.

- 3D and 2D color mapping with river-bottom path overlay.

- 2D profile section in both axial and circumferential direction.

- Quick, on-the-fly depth analysis: simply hover over each point to obtain local material loss.